Fall 2017: Building Livability

UTA researchers are creating a more sustainable, affordable North Texas for the future.

Skip to content. Skip to main navigation.

UTA researchers are creating a more sustainable, affordable North Texas for the future.

From carbon dioxide conversion to landfill mining, researchers at UTA are seeking viable alternative energy options.

Found in everything from space shuttles to dental fillings, composite materials have thoroughly infiltrated modern society. But their potential is still greatly untapped, offering researchers ample opportunity for discovery.

Within the particle showers created at the Large Hadron Collider, answers to some of the universe’s mysteries are waiting.

Model systems like pigeons can help illuminate our own evolutionary and genomic history.

UT Arlington's tiny windmills are bringing renewable energy to a whole new scale.

The stability of our highways, pipelines, and even manholes is reaching a breaking point.

Scientists believe they have discovered a subatomic particle that is crucial to understanding the universe.

UT Arlington researchers unlock clues to the human body’s most mysterious and complex organ.

UT Arlington researchers probe the hidden world of microbes in search of renewable energy sources.

Wounded soldiers are benefiting from Robert Gatchel’s program that combines physical rehabilitation with treatment for post-traumatic stress disorder.

Tiny sensors implanted in the body show promise in combating acid reflux disease, pain and other health problems.

Nanotechnology researchers pursue hybrid silicon chips with life-saving potential.

Biomedical engineers combat diseases with procedures that are painless to patients.

Illustration by Harry Campbell

How do you grow a transformative idea? It needs careful attention. It needs to be explored from every angle, and it needs room to expand to its fullest capacity. It needs the best and brightest thinkers on the job—nationally recognized experts who embrace innovation and foster collaborative partnerships. Transformative ideas need a place like The University of Texas at Arlington Research Institute (UTARI). As a research organization that focuses on getting technologies to the marketplace, UTARI links discovery, development, and technology commercialization. Now celebrating its 30th year, the institute boasts decades of innovative research and important breakthroughs. Guided by UTA's Strategic Plan 2020: Bold Solutions | Global Impact, the work done within its labs continues to produce discoveries and technologies that benefit the state of Texas—and well beyond—every single day by creating new products and companies that translate into more jobs and economic development.

The Institute for Predictive Performance Methodologies (IPPM), headquartered at UTARI and led by National Academy of Engineering member Kenneth Reifsnider, has continued to excel as a group of world-renowned experts in modeling, analysis, and prediction of composite and advanced material performance in structures and systems across application areas. This one-of-a-kind laboratory is helping companies like Triumph Aerostructures, Lockheed Martin, GE, Bell Helicopter, and Boeing predict failure in aerospace structures and turbine engines before they occur.

Through a Boeing contract, the IPPM is working with Andrew Makeev, professor of mechanical and aerospace engineering and director of the Advanced Materials and Structures Lab, to test and characterize composite components, which will allow researchers to predict when they might fail and help companies build longer-lasting aircraft.

"At the end of the research, Boeing and the Air Force want to understand and have confidence that our analysis can be used to predict the remaining useful life of composite airframe structures," Dr. Makeev says.

The capability of IPPM has further attracted over $1 million in funding from NASA and is expected to draw an additional $5 million in the next few years from that agency and the Department of Defense. Beyond the research funding, companies like Lockheed Martin, Triumph Aerostructures, Bell Helicopter, and Raytheon will use the technology and life prediction modeling methods to increase their markets and enable job creation in Texas.

"Now that UTARI has acquired this capability, it's something that we will exploit and better benefit from," says Paul Oldroyd, technical fellow at Bell Helicopter Textron. "We've had some isolated successes in failure prediction, but we could have had a lot more if we'd been willing to acknowledge the potential opportunities associated with the kind of collaborative effort possible with UTARI."

In addition to its collaborations in composites and advanced materials, UTARI continues to create and sustain relationships with companies based on its extensive expertise and focus in controls and sensors. The rich history in these research areas can be traced back almost to the beginning of the research institute when Frank Lewis, expert in controls, joined the organization in 1990 as the Moncrief-O'Donnell Endowed Chair. Through his work and that of many researchers and students throughout the years, UTARI developed and continues to contribute to the development of technologies that are essential to assistive robotic technologies, advanced manufacturing solutions, and unmanned systems.

An example of the former can be seen in a partnership between Texas Health Resources, the UTA College of Nursing and Health Innovation, and UTARI to develop assistive robot nursing aids for use in hospital settings and home environments to improve the well-being of patients and caregivers. Results from this research so far have garnered significant nationwide media attention.

The institute also maintains many partnerships with Texas small businesses focused on technology improvements to meet the growing needs of their customers. Through its collaboration with TechComb LLC, a UTA technology spinoff company, UTARI is at the forefront of bringing low-cost robotics learning concepts to K-12 classrooms and informal STEM learning environments. By leveraging its expertise in this area with North Texas stakeholder organizations, UTARI hopes to encourage and develop the future STEM workforce for Texas. Pilot studies involving hundreds of K-12 students and educators, in conjunction with Fort Worth Museum of Science and History and Arlington Public Libraries, have returned considerable participant response data linking increased STEM interest to this effort.

Likewise, UTARI's projects with Innovative Conveyer Concepts (ICC)—a small business out of Grand Prairie—are leveraging the institute's advanced manufacturing competencies in machine-vision software to yield cost savings solutions for the company, including a first-of-its-kind sorting solution for its customer's manufacturing facility in Houston. ICC reports a major positive impact on its day-to-day business and continues to be an active partner.

With small businesses Sprocket Air Works, VectorNav Technologies, and Zedasoft Inc., UTARI is providing unmanned systems expertise and capabilities to image-capture and process data from unmanned aerial vehicles (UAVs) for agricultural applications, automate object tracking on moving driverless vehicles, and provide airworthiness flight testing of custom UAVs.

"The key to success is developing strategic working relationships with business and industry," says Mickey McCabe, executive director of UTARI. "Without business and industry, our technology goes nowhere. They are the outlet for technology commercialization, and it's through their partnership that we can create jobs for Texas by developing new products, devising better ways to make products, and reducing the costs of manufacturing."

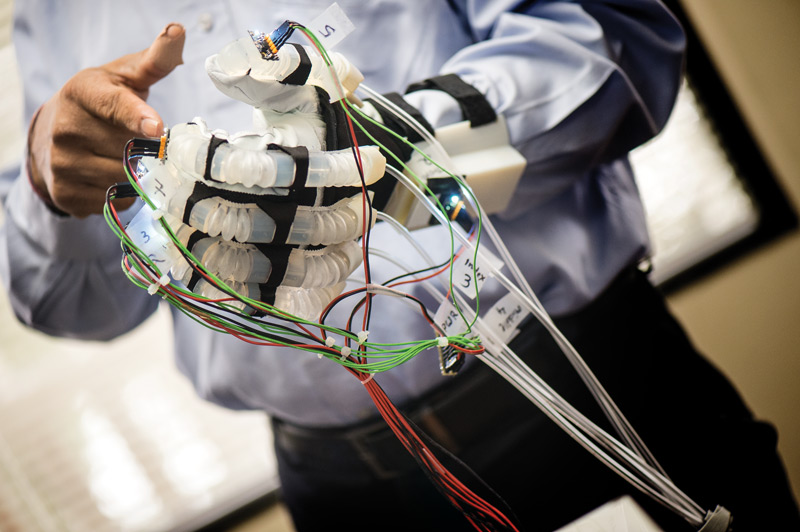

UTARI is looking at complex problems in the areas of preventative and rehabilitative care and is developing devices to improve the lives of patients, clinicians, therapists, and caregivers. Commercialization efforts are progressing with three UTARI developments in this area: the REHEAL glove, REHAB glove, and the Smart Seat Cushion. All are based on UTARI intellectual property and have received significant interest from the marketplace.

The portable REHAB glove created at UTARI can provide patients with prescribed therapeutic schemes.

The REHEAL glove is a transparent wound-healing glove that allows wound therapy through drug and fluid delivery and the extraction of excess fluid by negative pressure. Because it's transparent, doctors don't have to remove it as they would with bandages, which often tear tissue from the wound. Currently, UTARI is developing the manufacturing process for the REHEAL glove to begin the appropriate trials required to bring it to commercialization.

"Developing the manufacturing process is critical for clinical and pre-clinical studies of the REHEAL glove, which would be a Class 2 medical device and need FDA approval," says Muthu Wijesundara, chief research scientist at UTARI and leader of the project. "We are now moving beyond a lab prototype tested on volunteers to transition the technology for large-scale clinical human trials."

The REHAB glove is a motion glove that can actively adjust resistance for patients recovering from hand trauma, surgery, stroke, or cerebral palsy. This motion-therapy device is a portable, feedback-controlled, and programmable system capable of implementing prescribed therapeutic schemes developed by health care professionals.

Through a National Science Foundation grant collaboration, the University of North Texas Health Science Center is using the soft robotic technology to develop a rehabilitation device for children with cerebral palsy that can provide continuous measurements and data monitoring, characterize spastic resistance, and accommodate growth as needed.

The gloves were the center of attention at the recent American Society for Surgery of the Hand annual meeting held in Austin, Texas. Over a dozen surgeons and clinicians from across the nation expressed an immediate need for the REHEAL glove. UTARI is currently working to develop sufficient quantities of each glove for clinical trials. Recently, the University received a $227,000 grant funded through the federal government's Medical Technology Enterprise Consortium to develop the manufacturing process for the REHEAL glove.

The institute's work in soft robotic devices also extends to other applications, including the prevention of pressure ulcer formation for those with spinal cord injuries. Researchers have developed the Smart Seat Cushion to provide relief for wheelchair users whose impairments were caused by spinal cord injuries or other neurological complications.

In collaboration with Rory Cooper, director of the Human Engineering Research Laboratories at the University of Pittsburgh, UTARI has manufactured prototypes of the Smart Seat Cushion that will be tested on patients with mobility impairments to help them combat the formation and lessen the prevalence of pressure ulcers. The project has already yielded significant results toward commercialization.

"The research and development of the Smart Seat Cushion will be beneficial to all people with mobility impairment," Dr. Cooper says. "The less someone has to worry about the pain of ulcers, along with expensive and inadequate treatments, the more they can focus on other aspects of getting on with their lives and pursuing their ambitions."

Bolstered by decades of scientific inquiry and discovery and facing a new decade in an ever-evolving, increasingly complex society, UTARI remains steadfastly committed to its mission to advance technology for the advancement of humankind.

"UTARI's expertise in fields that are critical to the Dallas-Fort Worth area like aerospace, manufacturing, robotics, and unmanned systems is helping industry and small businesses grow and expand, generating new jobs and economic development," says Duane Dimos, vice president for research. "Our research scientists in biomedical fields are also developing breakthrough technologies in the health arena that are moving into the market to help improve quality of life for everyone."