Fall 2017: Building Livability

UTA researchers are creating a more sustainable, affordable North Texas for the future.

Skip to content. Skip to main navigation.

UTA researchers are creating a more sustainable, affordable North Texas for the future.

From carbon dioxide conversion to landfill mining, researchers at UTA are seeking viable alternative energy options.

Found in everything from space shuttles to dental fillings, composite materials have thoroughly infiltrated modern society. But their potential is still greatly untapped, offering researchers ample opportunity for discovery.

Within the particle showers created at the Large Hadron Collider, answers to some of the universe’s mysteries are waiting.

Model systems like pigeons can help illuminate our own evolutionary and genomic history.

UT Arlington's tiny windmills are bringing renewable energy to a whole new scale.

The stability of our highways, pipelines, and even manholes is reaching a breaking point.

Scientists believe they have discovered a subatomic particle that is crucial to understanding the universe.

UT Arlington researchers unlock clues to the human body’s most mysterious and complex organ.

UT Arlington researchers probe the hidden world of microbes in search of renewable energy sources.

Wounded soldiers are benefiting from Robert Gatchel’s program that combines physical rehabilitation with treatment for post-traumatic stress disorder.

Tiny sensors implanted in the body show promise in combating acid reflux disease, pain and other health problems.

Nanotechnology researchers pursue hybrid silicon chips with life-saving potential.

Biomedical engineers combat diseases with procedures that are painless to patients.

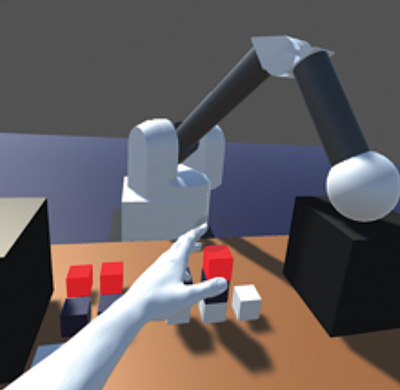

In the manufacturing world, automated technology makes up an increasingly large part of the workforce. But what about the people doing their jobs alongside those robots? Two computer science and engineering researchers at UTA received a nearly $1 million National Science Foundation grant to develop a training system that will school humans on just that.

Professor Fillia Makedon and Associate Professor Vassilis Athitsos are building a smart, robot-based system that assesses workers as they perform simulated manufacturing tasks. Known as iWork, it calculates a person's cognitive skills, like attention and task awareness, plus their physical and collaborative abilities to team with a robot.

"iWork will assess and train both human workers and robot co-workers as they collaborate, producing personalized, low-cost vocational training solutions that have a huge societal impact and affect many economic sectors," says Dr. Makedon.

The team has conducted vocational simulation experiments for years, studying ways to train and prepare people for industries where a worker must safely and efficiently collaborate with advanced robots. The system's modular, easily customizable closed-loop "behavior discovery" data flow has four phases: assessment, recommendation, intervention, and evaluation. After each cycle, iWork recommends—with the assistance of a human factors expert—personalized interventions for vocational training and rehabilitation.

The system, Makedon says, "could impact millions of people, including those facing a type of learning or aging disability or returning from military service with some health issues."