FEATURE

STORIES

From laboratory to marketplace

How Maverick researchers transform their discoveries into commercial success

echnology development and commercialization are the new drivers of economic growth for countries that want to succeed in an increasingly competitive global market.

That’s good news for universities like UT Arlington, which has accelerated its research efforts in the past decade.

Research expenditures reached $66.5 million in 2007-08. Faculty disclosures of intellectual property and new technologies have increased from 12 to 60 in the past six years.

Last year, research at UT Arlington yielded 30 patent applications and start-ups for 10 companies with gross license income of more than $8 million.

“As a research institution, the University works to contribute to society by improving quality of life through science, technology, medical diagnostics and health-care initiatives,” said Ron Elsenbaumer, vice president for research and federal relations. “Our focus is to have more ideas, more discoveries and more disclosures from faculty and students.”

Discoveries and disclosures that may lead to commercial ventures.

There are many ways for technology to go from the mind of a UT Arlington researcher to the marketplace. But generally the life cycle of a product follows the same steps: research, discovery, patent, licensing, development, commercialization and market.

The challenge following the discovery is knowing if a potential product is novel, ready to patent, and has market potential and perceived value. UT Arlington researchers rely on the Intellectual Property Disclosure Committee for help.

“The committee has experience with the patent process and reviews the inventions and makes an independent determination if an invention is ready to patent and has value,” Dr. Elsenbaumer said. Applying for a patent is expensive and time-consuming—as much as $30,000 for each application and taking up to three years for approval.

Once an invention is patented, it’s time to decide how to commercialize it. Licensing the patent to an outside company, setting up a company through a venture capital fund or starting their own firm using a technology incubator are among the avenues UT Arlington researchers have taken.

A good night’s sleep

Bioengineering Department Chair Khosrow Behbehani forged an early path into commercialization.

In the 1990s he licensed technology for an automatic positive airway pressure (APAP) machine to treat sleep apnea to Respironics, a global provider of sleep and respiratory solutions. Its Sleep and Home Respiratory Group offers oxygen, ventilation and monitoring products for patients with chronic respiratory diseases.

- Vice President for Research and Federal Relations Ron Elsenbaumer

Sleep apnea sufferers experience pauses in breathing that wake them up repeatedly. The affliction has been medically linked to hypertension, heart failure and stroke. Dr. Behbehani’s APAP monitors a sufferer’s breathing pattern during a typical night of sleep and adjusts the airway pressure automatically to prevent the pauses in breathing and subsequent waking.

Behbehani, who also is a bioengineering professor, began his sleep apnea research in 1987 when the disorder was relatively unknown.

“At the time, the treatment was a small ventilator that applied constant pressure to the airway,” he said. “Patients complained that the pressure applied to the airway via a nasal mask was too much and made sleeping uncomfortable. Most simply didn’t follow the treatment.”

So Behbehani and his students, in collaboration with medical experts from Sleep Consultants Inc. in Fort Worth, created the APAP system to continually adjust respiratory airflow pressure based on a patient’s needs. The device could even sense if the patient had been drinking alcohol or suffered from nasal congestion.

They patented the device and were approached by Respironics, which wanted to license the technology. Working with UT Arlington’s Office of Technology Management, Behbehani signed a licensing agreement that allowed Respironics to manufacture the APAP machine and make it available to the growing number of sleep apnea patients.

The office helps faculty in three areas: finding potential licensees for University technologies and negotiating licenses, filing patent applications and commercializing licenses via a start-up company or other means.

Behbehani continues his research to enhance the device’s capabilities and has received other patents for sleep apnea prevention techniques that are available for licensure through the Office of Technology Management.

In addition, he has expanded his research to focus on sleep apnea detection using a patient’s electrocardiogram readings. The ECG records the electrical activity of the heart over time, but Behbehani and his colleagues have shown that the heart can also be studied for key markers that indicate apnea.

They received a patent for this invention in March 2008 and filed for another in 2007 that enhances it.

A healthy coating

Chemistry and biochemistry Professor Richard Timmons wasn’t sure how to approach commercialization of his patented plasma coating technology for medical and industrial applications. That was until Emergent Technologies approached him in 2007.

The venture capital firm was ready to use money from its Emergent Technologies Fund IV to commercialize multiple technologies derived within University of Texas System institutions. ETI saw potential in Dr. Timmons’ more than 20 years of research in surface chemistry.

“We do molecular tailoring of surfaces,” said Timmons, who has received 12 patents in the area and has an additional four pending. “Surface interaction is important, especially for biomaterials where the body’s response to implants is a concern.”

He has worked on catheters, stents, breast implants and sensors, all of which become less effective if matter from the body coats them. For instance, a properly working sensor can become unreliable if biofilms cover its surface.

His solution: deposit specialized plasma polymer films to help control the chemical interactions between the surfaces of the implants and the bodily tissue. Each device has a custom-designed, molecularly tailored coating to suit its environment. “We identified a number of potential applications for Dr. Timmons’ technology in the medical and industrial markets,” said Tony Taylor, ETI’s senior vice president of business development. So Timmons signed an agreement to license five patents to ETI, effectively forming AeonClad Coatings, LLC.

AeonClad creates highly specialized surface coatings for medical, industrial and other applications. Timmons is chief scientific officer, and he continues his work with three other researchers. AeonClad rents space in Science Hall, and its scientific efforts include innovations involving polymer surface coatings.

Current studies include the potential application of coatings for controlled drug release in patients.

“By being very exact with respect to film thickness and density, we have demonstrated an ability to provide precise drug release rates in lab conditions,” Timmons said. The new technology must now be examined in living organisms, which will involve cooperative studies with pharmaceutical companies.

As for the business side, Timmons relies on the same principles as other companies in ETI’s portfolio. ETI provides administrative and financial support for start-up companies. This includes a full staff of business professionals with experience in conducting market research, managing intellectual properties, identifying collaborative partners and implementing marketing and business plans.

ETI has launched other life sciences companies, several formed using university-based technologies. Its Emergent Technologies Funds I, II and III supported technologies licensed from the University of Oklahoma Health Sciences Center, Texas Tech University and other entities in Lubbock, the Texas Panhandle and West Texas. Funding helped start 10 portfolio companies, all of which still operate.

Like those, Timmons and AeonClad have a long journey before being classified as a success in the $5-billion-a-year medical device coating industry. Through ETI, they have a viable map to follow.

Oil change

In 1999, Platinum Research Organization, Inc. came to UT Arlington for research to develop a line of high-performance lubricants and additives. What PRO found were two researchers working on separate projects with a lot of potential.

“They came to us looking for capabilities in applied science and found the skills and instrumentation they needed,” Elsenbaumer said. “When we talked to them and understood their problem, it was very clear we could do it all here at UT Arlington.”

PRO supported Elsenbaumer and materials science and engineering Professor Pranesh Aswath as co-investigators for its scientific team. They began working collaboratively on nanolubricants.

“We created a new line of research at UT Arlington that has been quite successful,” Dr. Aswath said. “We are now recognized nationally and internationally for our research capabilities and for what we have been able to achieve.”

The duo, who have received continuous research funding from PRO since 1999, work in tribology, the science and technology of interacting surfaces in motion. Their efforts include the study and application of the principles of friction, lubrication and wear. Through their research, they have created additives that enhance the anti-wear, anti-corrosion and extreme pressure performance of oils and greases.

Their oil additives are designed to safeguard the environment by reducing phosphor and sulfur deposits in a vehicle’s catalytic converter, thus extending its life and preventing emissions like carbon monoxide, nitrous oxides and hydrocarbons from escaping the tailpipe. The additives are said to have better anti-wear properties and are cheaper and less environmentally hazardous than current additives. In addition, they are less expensive and increase performance of industrial greases by eliminating an expensive extreme pressure additive.

The work has produced eight patent applications and a portfolio of products that support PRO’s mission to design, develop and commercialize patented, high-performance and environmentally friendly additives for lubricants and coatings. The products are sold under the name TechroBond.

Founded in 1996, PRO became a publicly traded entity on the over-the-counter bulletin board, or OTCBB, in 2007. The same year, the Environmental Protection Agency reviewed and certified TechroBond, clearing it for production and distribution in the United States. PRO achieved its first step toward global commercialization of the brand by signing a worldwide distribution agreement for the industrial greases market.

But Elsenbaumer and Aswath have one final hurdle to clear.

“Technology takes a long time to develop for the marketplace,” Elsenbaumer said. “There is a great deal of effort and investment involved in new product development, and market acceptance is often difficult.”

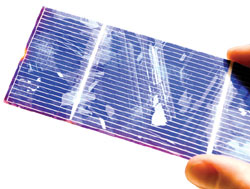

Super solar power

Electrical Engineering Associate Professor Meng Tao isn’t afraid to take risks when it comes to commercializing his techniques for creating more efficient solar cells.

He and his business partner recently created ZT Solar with support from the Texas Ignition Fund, formed by the UT System in 2007 to spur commercialization of inventions. Dr. Tao also works with Tech Fort Worth, a nonprofit business incubator that assists technology start-ups.

Tech Fort Worth identifies technologies with high potential for marketplace success and then works with companies to create business plans, develop marketing strategies, build management teams and launch proprietary technology into the economy.

Tao chose the technology incubator route—rather than licensing the technology to another company—to give his research a better marketplace future. He also was impressed with Darlene Ryan, executive director of Tech Fort Worth, and her experience with starting companies from scratch.

“She has the know-how we don’t have based on her years of experience running a small business,” he said.

Ryan was founder and CEO of a pharmaceutical manufacturing company from 1994-2006 and successfully raised bank financing and private equity, applied for patents and negotiated licenses of her company’s technology. Through her expertise, Tao hopes to bring to market a more efficient solar cell to convert sunlight to electricity using affordable materials and a new surfacing technique.

He creates a surface texture on solar cells using spherical microparticles that can be applied to all types of solar cells to reduce reflection.

“This improves sunlight collection, often by as much as 10 percent, because the spheres are omnidirectional,” he said. “They can absorb sunlight from any direction even on a fixed-orientation panel like those used on traffic signals and rooftops.”

Tao is seeking patent protection for the process, looking for a CEO for ZT Solar and exploring additional funding. The company received a Small Business Innovation Research grant from the National Science Foundation earlier this year. The SBIR provides funding to small businesses for research and development with commercialization potential.

ZT Solar also plans to apply for support through the Texas Emerging Technology Fund, a program that provides seed capital to Texas businesses for commercialization of emerging technologies. If ZT Solar receives the funding, it will be able to build a production-ready coating machine to test how well the technique works on commercial solar cells.

“We have to demonstrate to the different manufacturers how our technology can enhance the efficiency of their cells,” Tao said. “But there is a cost issue. We have to show companies that the monetary gains they receive offset the costs of production.”

He hopes to have a product on the market by 2010, a lofty goal considering the commercialization process usually takes 10-15 years.

That’s a relatively short time span for a technology—like many others developed at UT Arlington—with potential to yield life-enhancing advancements for generations to come.

— Becky Purvis

Other Stories

Deans named

for School of Urban and Public Affairs, Honors College

Study shows teen victims seek friends' help

United they stood

Supporters convinced legislators to trumpet the University’s research strengths

UT Arlington's new mace

Art meets Academia

Search

Contact Us

Office of University Publications

502 S. Cooper St.279 Fine Arts Building

Box 19647

Arlington, TX 76019-0647