UTA aerospace engineer receives Army Research Lab grant to advance limitations of computed tomography

A UTA aerospace engineering researcher will improve reconstruction algorithms and software techniques to produce breakthroughs in computed tomography scanning, which will lead to better recognition of manufacturing flaws and structural damage of composites.

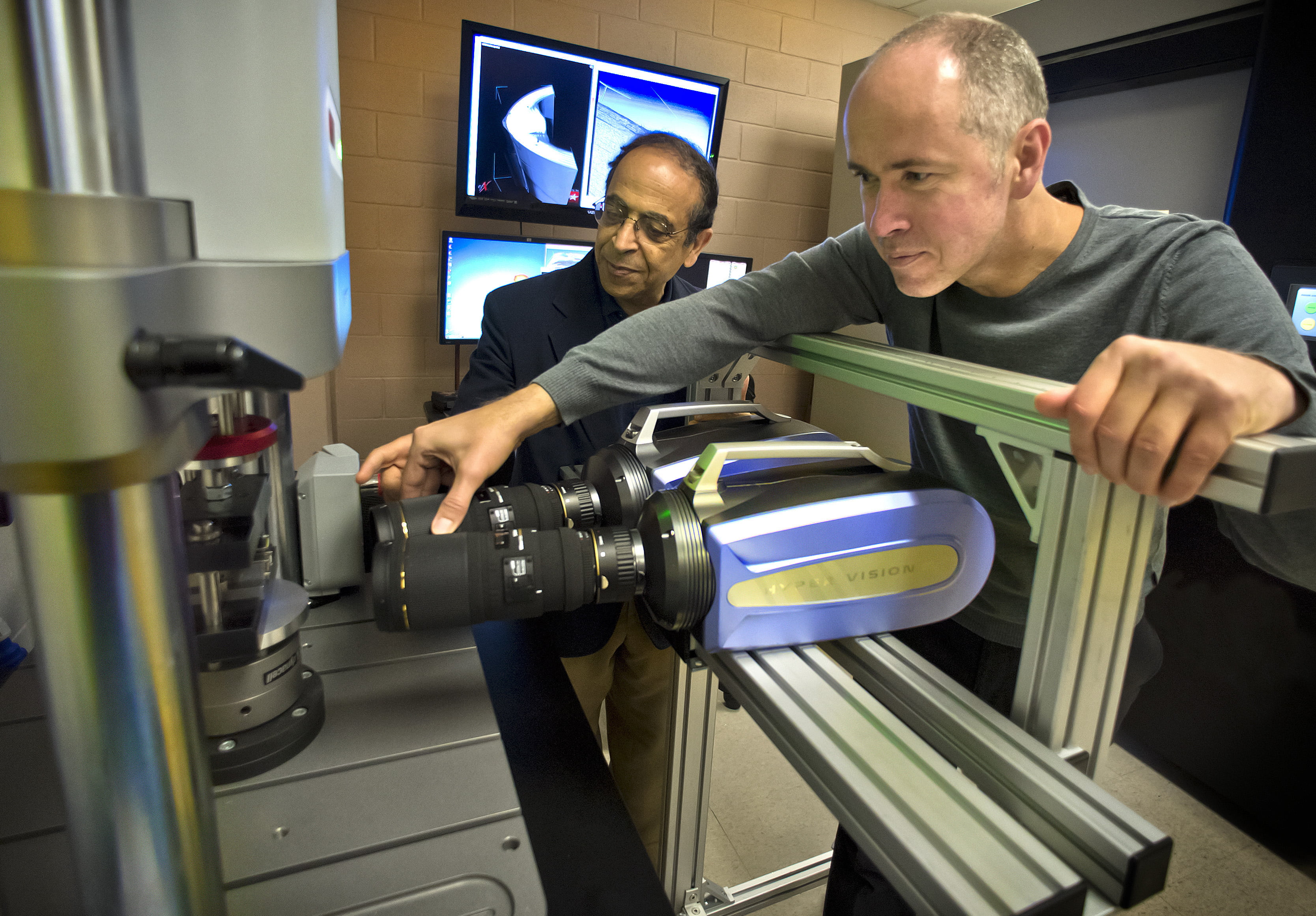

Andrew Makeev, professor in the University of Texas at Arlington’s Department of Mechanical and Aerospace Engineering, received a $900,000 grant from the Army Research Lab to address the Army’s need for better structural diagnostics and life assessment in composite aircraft parts.

Makeev, who also directs UTA’s Advanced Materials and Structures Lab, will lead the project.

He said UTA’s effort will focus on developing effective tools for high-resolution, one-sided computational tomography- or CT-based non-destructive inspection or NDI.

“One-sided scanning will improve the versatility of CT-based microstructural material characterization and structural diagnostics to virtually unlimited object in-plane dimensions, and help the development of game-changing NDI systems,” Makeev said.

Currently, composite aircraft structures are susceptible to damage precursors like porosity and voids, and sustaining fiber-waviness. Those discontinuities may evolve into structural damage in the form of cracks and delamination or composite layer splitting.

X-ray CT has proven to be the only 3D industrial nondestructive inspection which has reliable micro resolution and allows for automated interpretation of the inspection results including the listed flaws. However, the current micro-focus CT technology is based on full scanning or 360 degrees around the object, which limits the technology to small cross sections and prevents accommodation of large structures.

Even small objects, which can be scanned in the existing micro-CT facilities, sometimes do not allow for sufficient magnification of the microstructure during the full scanning. However, available limited-angle reconstructions lose definition and often become erroneous during one-sided inspections.

“We believe that to advance composite aircraft structural certification, the analysis must capture manufacturing complexity and variability of flight-critical components and structure,” Makeev said. “Recent improvement in computing power and advances in X-ray CT reconstruction make it possible to develop high-resolution, one-sided CT inspection technology breaking through the object size limits of X-ray CT. It also offers the long-sought automation for composite aircraft structures.”

Erian Armanios, chair of the Department of Mechanical and Aerospace Engineering, said Makeev’s work answers the call of UTA’s Strategic Plan 2020 for Bold Solutions.

“Inspection of large composite components in a single run addresses a timely and critical need,” Armanios said. “Dr. Makeev’s research provides CT software solutions that can combine high degree of automation with high degree of accuracy – key end user requirements.”

The U.S. Army and helicopter industry are facing the challenge of replacing more than 6,300 military vertical lift aircraft.

Earlier this year, Makeev received a separate $600,000 grant from Boeing to assess durability and damage tolerance of composite structures for composite airframe life extension.

Makeev has shouldered many research projects with companies that are especially focused on composite materials and structures. He has current or past grants with Boeing, Lockheed Martin Aeronautics, Sikorsky Aircraft and Bell Helicopter Textron.

During his six-year tenure at UTA, Makeev has been conducting pioneering theoretical and experimental work sponsored by the U.S. Army, U.S. Navy, U.S. Air Force and aerospace industry at an average rate of $1 million per year in external funding. His work includes integration of design and manufacturing processes to improve performance of composites, advanced material technologies, material characterization, structural diagnostics and prognostics.